Overview

Most critical Horizontal Directional Drilling (HDD) projects in North America continuously monitor drilling fluid annular pressure during construction for mitigating risk of inadvertent returns (IR) of drilling fluids to the surface or to waterbodies (which is also sometimes called hydrofracture, or “frac out”). Downhole tooling automatically records “real-time”, or “as-built” pressure data throughout the length of the HDD crossing and relays it back to the driller. While this data is extremely important during the construction of an HDD, the data is also useful to determine whether the theoretical drilling fluid and confining pressure calculations used by the HDD designer are valid. This article will give readers an insight into recent findings which show how the measured data compares to the industry standard calculated values.

To begin, the authors collected this as-built annular pressure data from past HDDs and compared it to the calculated theoretical drilling fluid pressure within the annulus of the borehole. Results of this analysis show the accepted drilling fluid models (in particular, the Bingham Plastic model) used to calculate the annular pressure during drilling generally compare well to the data obtained.

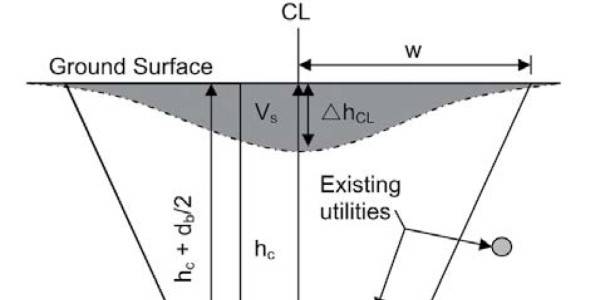

Although the accepted models accurately predict actual fluid pressure downhole, the accurate prediction of confining pressure (ie hydraulic fracture) is a different story. In order to assess the accuracy of the confining pressure calculations the authors have used as-built annular pressure data to determine the date, time, and pressure magnitude of actual hydraulic fracture occurrences in HDD crossings. Through careful evaluation, these occurrences have been isolated within the as-built data and compared to the predicted hydraulic fracture pressure calculated by the industry-standard “Delft” equation using site specific geotechnical parameters.

Results of the analysis of as-built data show that in most, if not all cases the “Delft” solution over-predicts the actual hydraulic fracture pressure, which can lead to severely unconservative designs and fluid release issues during construction. Additionally, the suggested factors for the “Delft” equation variable Rp,max of 1/2 and 2/3 multiplied by the overburden height for clay and sand, respectively, have not been previously investigated and compared to actual hydraulic fracture data. Contained within this research, the Rp,max value is modified to determine at what value the Delft equation best predicts the actual hydraulic fracture pressure.

Authors

Stefan Goerz, M.Sc., P.Eng, P.E, CCI Inc.,

Nicolas Boelhouwer, P.Geo, CCI Inc.,

Justin Taylor, P.Eng, P.E, CCI & Associates Inc